FenDa Automatic bag-in-box filling machines filling by weight, are essential to any bag in box filling and packaging line and offer a variety of upgrade options to meet the needs of your concentrates, purees, paste, ketchup, soft ice cream, condensed milk, cheese sauce, Sauces , condiments, Liquid eggs, mayonnaise, yogurt, ice cream production.

Designed to weight-based fill a wide range of pumpable products, both thin liquid and thick liquid, food and non-food, into single bags with 1-inch spouts.

Bag-in-box (BIB) packaging is a convenient and economical alternative to bottles, significantly reducing packaging storage and distribution costs.

FenDa / Fangding Packaging Technology provides you not only with bag-in-box and spout pouches but also provide you with automatic and semi-automatic bag-in-box filling machines for the safest and most convenient filling and packaging process.

Whether you opt for the high-speed BIB filler or the semi-automatic filler for the pre-vacuuming and product-filling operation, you can count on having years of trouble-free performance, the lowest operating costs, complete flexibility and control over the operation, and a wide range of standard features.

Bag-in-box packaging is a convenient and economical alternative to bottles, significantly reducing packaging storage and distribution costs.

Automatic or semi-automatic, FenDa bag-in-box filling machines are essential to any bag in box filling and packaging line and offer a variety of upgrade options to meet the needs of your juice and puree production.

The operator inserts the empty bag into the spout holder and activates the filling sequence. The system locks the bag in place, removes the cap and inserts the product valve. Any residual air is removed by the vacuum and the product flow begins by means of integrated pump. When the bag is filled to the desired volume, the product flow is shut off, the bag is recapped and the operator takes the filled bag from the holder.

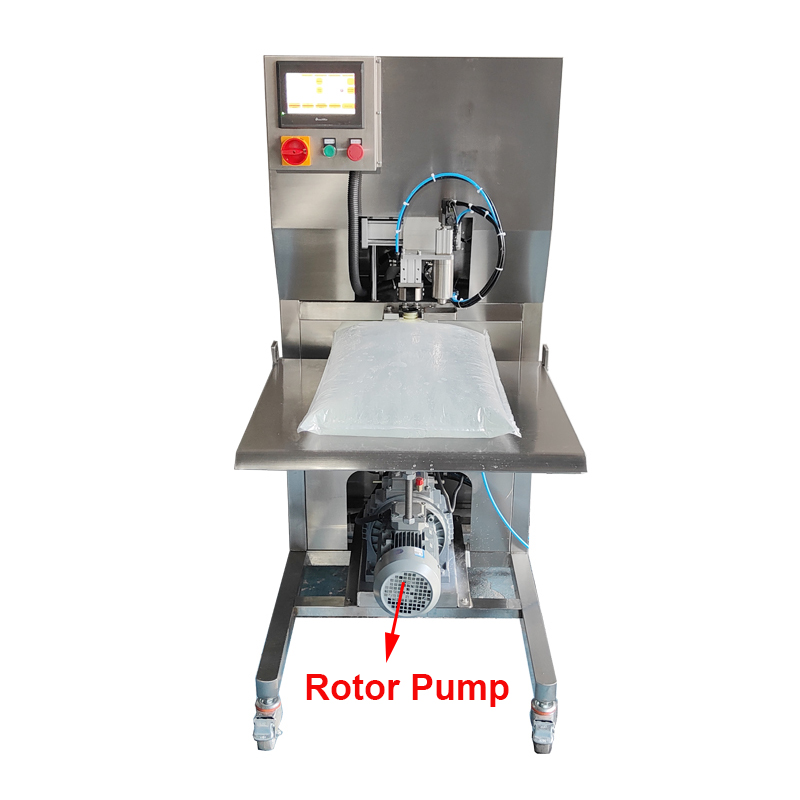

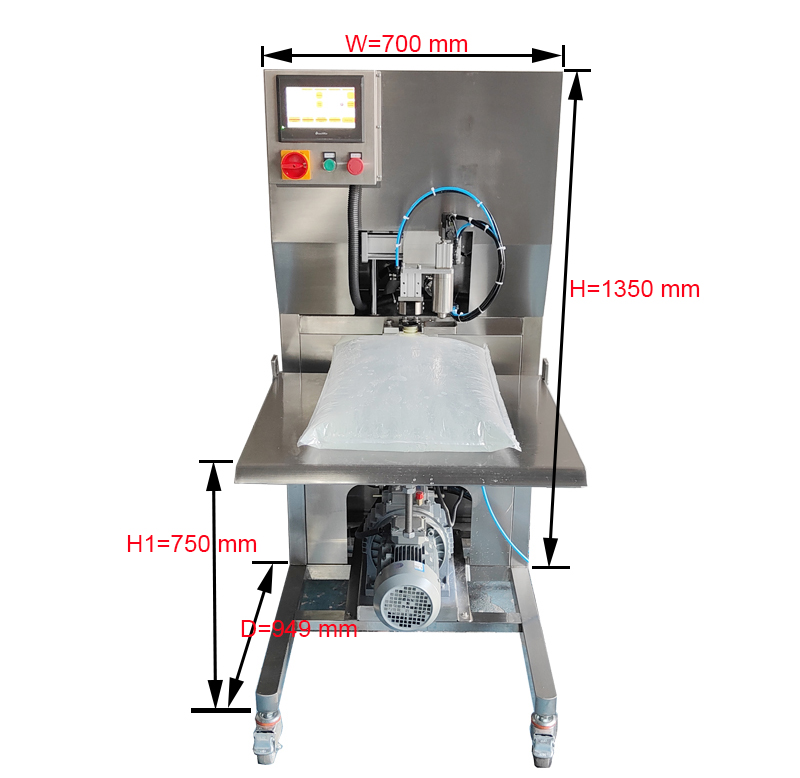

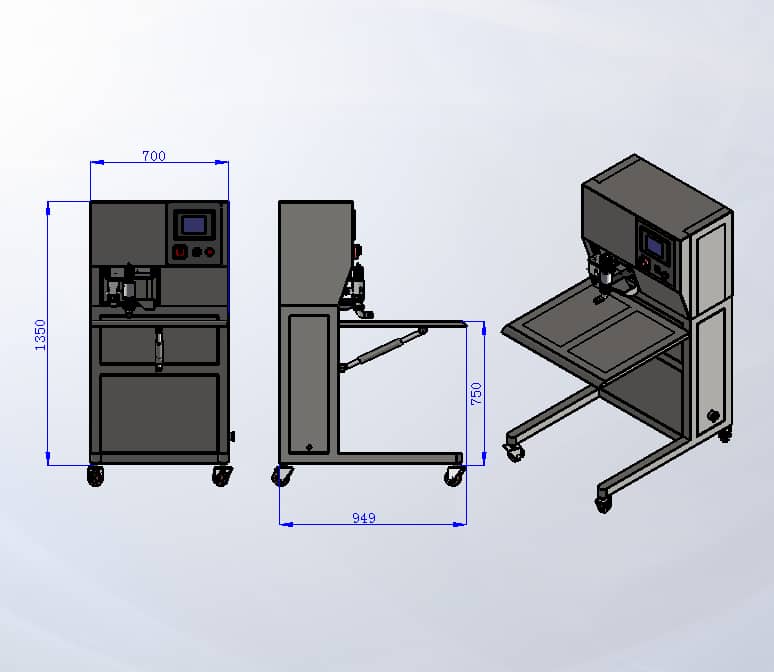

Different elements such as flowmeter, and (rotor) pump can be used, depending on the filling application. Easy to use and maintain, this advanced filling and packaging technology greatly facilitates the work process and complies with the highest food-safety standards, ensuring top BIB filling experience and product quality achieved with minimal effort.

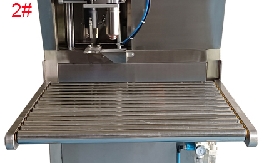

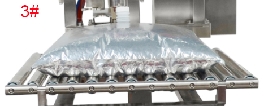

Automatic bag-in-box filler

Available with a single or double head, the automatic high-speed BIB filler is designed for production facilities in pursuit of efficiency, reliability, and high-quality filling. All parameters are adjustable, allowing complete flexibility and control over the filling process.

Once the operator sets the bag in place and presses the START button, the filling machine automatically performs the complete cycle: bag opening, pre-vacuuming to remove all the air from the bag, product filling, and closing. Filled and capped, the bag is manually removed from the machine.

Filling up to 220 bags per hour, the bag in box (BIB) filler uses high accurate electronic flowmeter and controller for absolute reliability and ease of use.

AUTOMATIC BAG-IN-BOX FILLER TECHNICAL PARAMETER (FDGZMT002) |

|

|

Number of Filling head(s) |

1 |

|

Filling Range |

1–30 KG |

|

Filling Precision |

±1% |

|

Max. Speed (bags per hour. water) |

220 |

|

Filling with flow/mass meter |

scale (weight) |

|

Material Entrance Pressure |

0.3–0.35 Mpa |

|

Operating Pressure |

0.5–0.6 Mpa |

|

Supply Voltage |

AC220V/50Hz ±10% |

|

Air Consumption |

≥ 0.36 m³/min |

|

Filling temperature range |

≤ 95 ℃ |

|

Power of One Head |

1.5 KW |

|

TYPICAL APPLICATIONS |

• Concentrates, purees, paste, ketchup • Dairy (soft ice cream, condensed milk, and cheese sauce) • Sauces and condiments • Liquid eggs, mayonnaise |

Contact: Sales Department

Phone: +86-577-68639193

Tel: +86-136-1707-2299

Email: info@fdpack.com

Add: Buildings 1-3, etc.,No.4225-4393, Century Avenue, Longgang, Wenzhou, Zhejiang, China

We chat